Well & Asset Integrity

Services

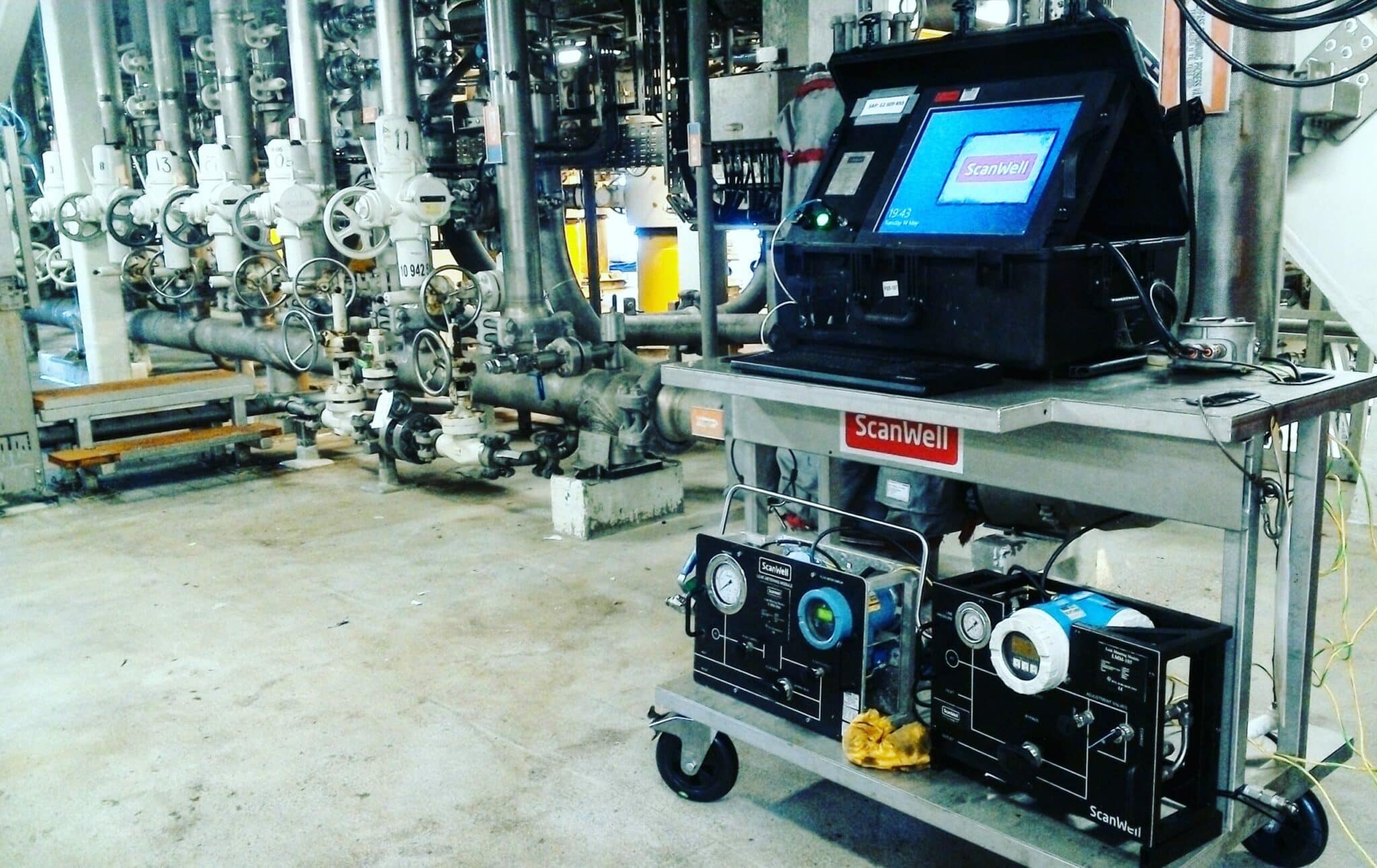

ScanWell offers advanced interventionless solutions for well integrity diagnostics, helping operators to monitor and protect the structural and functional integrity of their wells. Our advanced technologies provide high-quality diagnostic information on potential integrity breaches, minimizing operational risks without requiring intrusive interventions.

With these innovative tools, operators can proactively identify and resolve issues, ensuring secure hydrocarbon containment, safeguarding personnel and assets, and adhering to industry safety and environmental regulations.

Annular Forensics / Source Identification

Annular forensics helps identify the source of well integrity problems, such as leaks, by analyzing the fluids contained in the annular space. ScanWell provides advanced solutions to sample and diagnose these conditions, allowing operators to take targeted actions and effectively maintain well integrity.

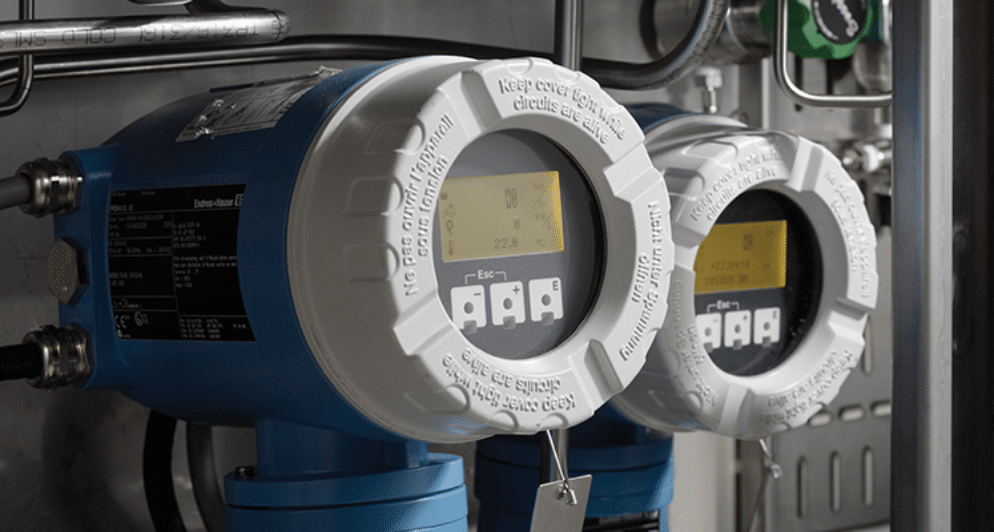

Annular Integrity Checks

ScanWell offers proprietory solutions to perform annulus integrity checks without the need for well intervention, enabling operators to assess well conditions and implement proactive surveillance and risk mitigation strategies efficiently.

Chemical Injection Line Testing

ScanWell offers non-invasive solutions to monitor the integrity of downhole chemical injection lines, allowing operators to detect potential integrity issues early without the need for well intervention.

Conductor & Riser Integrity Checks

ScanWell provides advanced solutions for conducting integrity checks on conductors and risers, enabling operators to monitor structural health and identify potential risks

Hanger Leak investigations

Hanger leaks are a common integrity concern in aging wells. ScanWell provides interventionless diagnostic techniques to accurately assess the size and location of leaks at or near the casing hanger, enabling timely detection and mitigation

Leak Point Identification

Leak point identification is crucial for evaluating the risks associated with leaks and determining the appropriate mitigation strategies. ScanWell’s interventionless, multi-method approach provides accurate leak point information, enabling operators to assess risks and choose effective solutions without intrusive interventions.

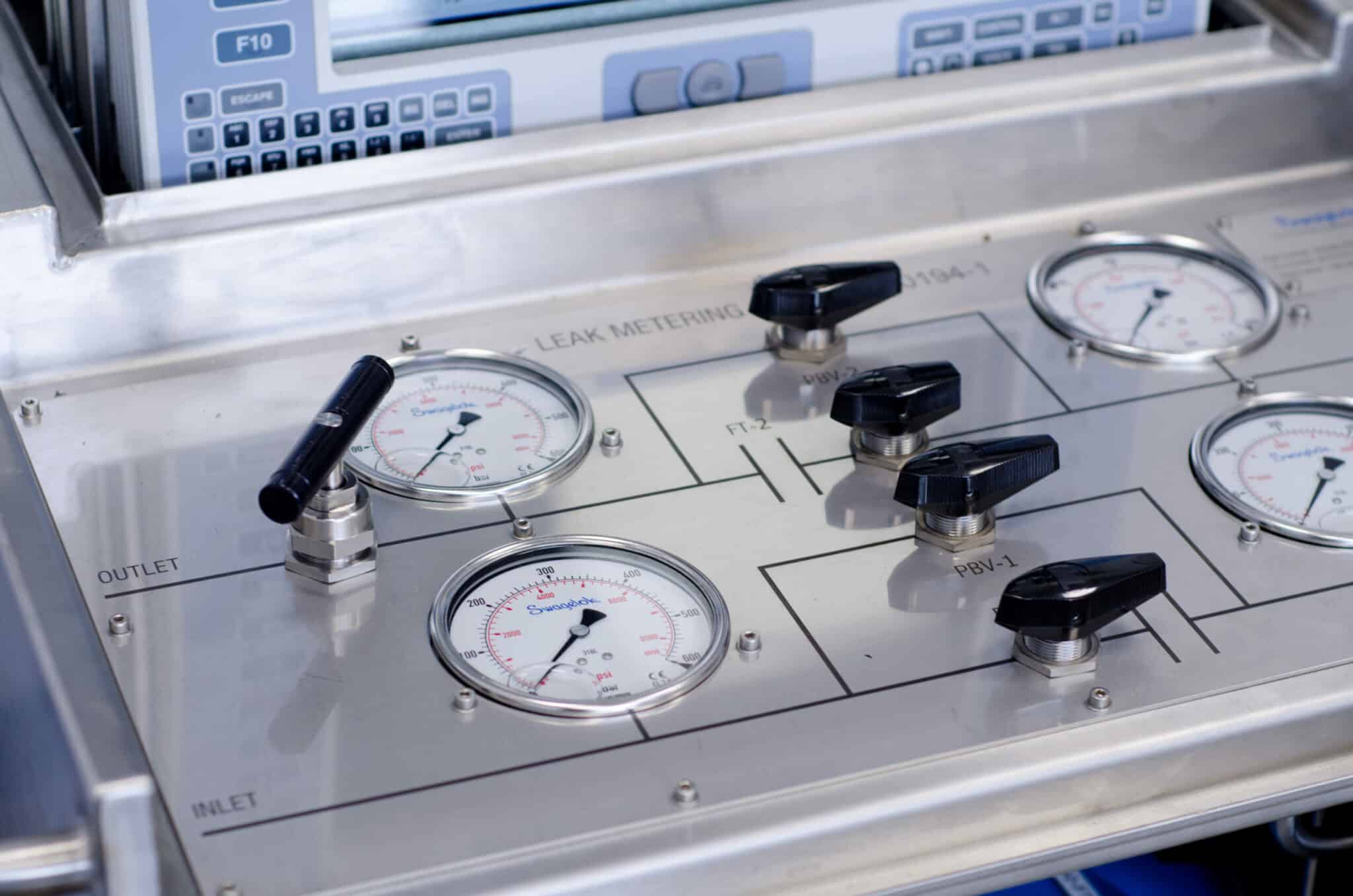

Leak Rate identification & Risk Evaluation

Leak rate information is essential for assessing risks related to sustained casing pressure scenarios. ScanWell offers proprietary methods for accurate leak rate quantification, eliminating the need for conservative pressure build analysis.

Patch & Seal Verifications

Patch and seal verification is vital for confirming the effectiveness of integrity repairs. ScanWell provides advanced methods for non-intrusive verification, ensuring the reliability of patches and seals without the need for invasive procedures.

Tubing Integrity Checks

Tubing integrity checks are essential for ensuring safe and efficient well operations. ScanWell offers advanced, interventionless solutions to assess tubing conditions, enabling operators to detect potential issues and take proactive measures without disrupting production.

Top Up / Bleed off exercises

Top-up and bleed-off exercises are crucial for maintaining well pressure and fluid balance. ScanWell offers innovative techniques to evaluate restricted volumes, optimizing top-up and bleed-off routines for improved efficiency and reduced operational risks.

Wellhead / Xmas Tree Inspections & Maintenance

Wellhead and Christmas tree inspections and maintenance are critical for ensuring safe and reliable operations. ScanWell provides advanced, interventionless solutions to assess the condition of wellheads and Xmas trees, helping operators optimize maintenance schedules and prevent potential failures.

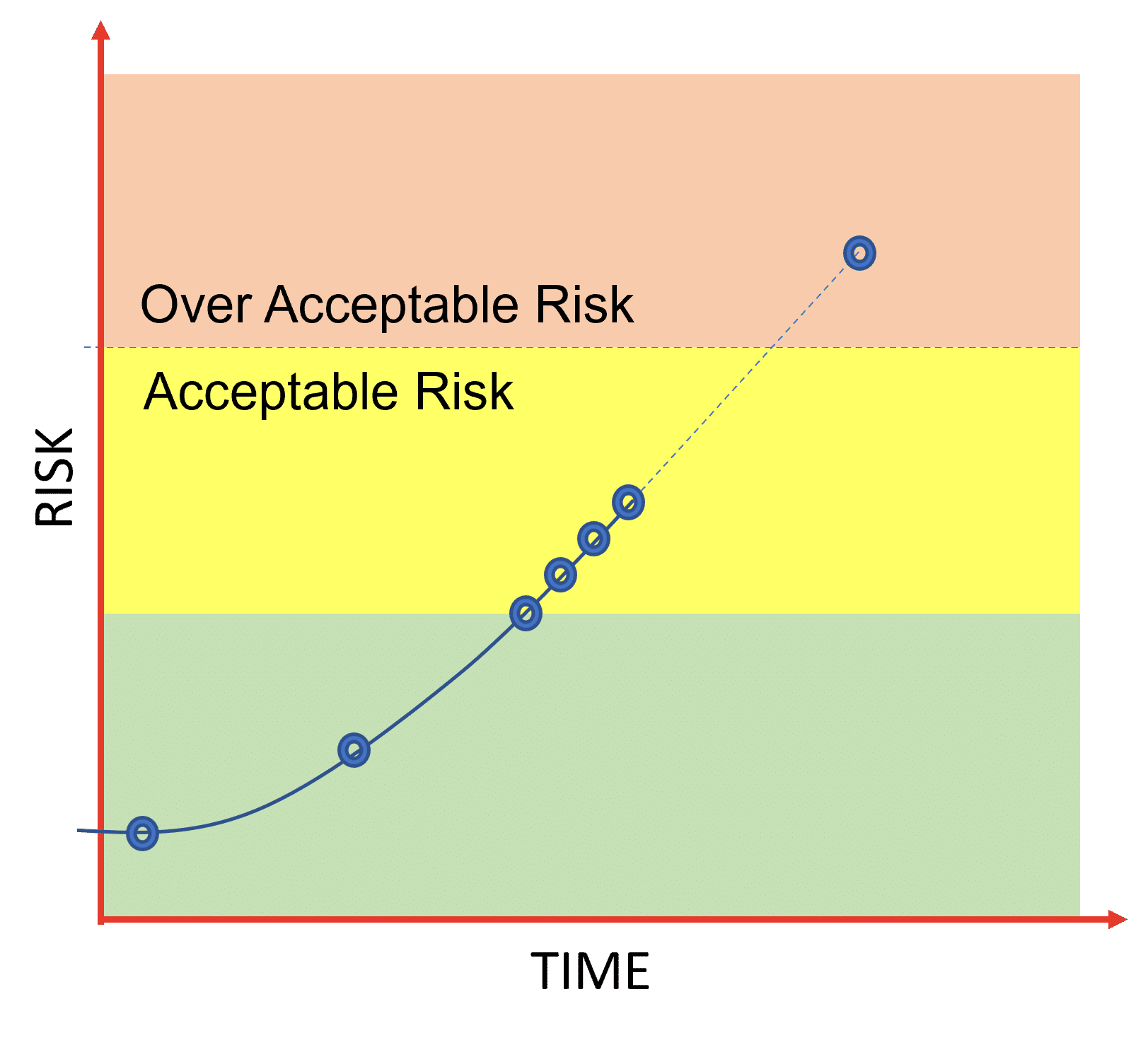

Well Health Certification and Risk Trending

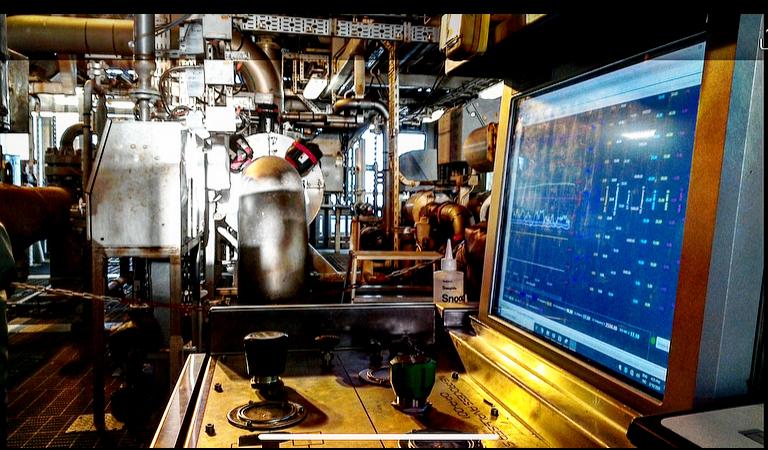

Well health certification and risk trending are essential for managing well integrity over time. ScanWell offers innovative solutions to monitor well conditions, track risk trends, and provide comprehensive assessments, enabling operators to make informed decisions and maintain long-term well safety.

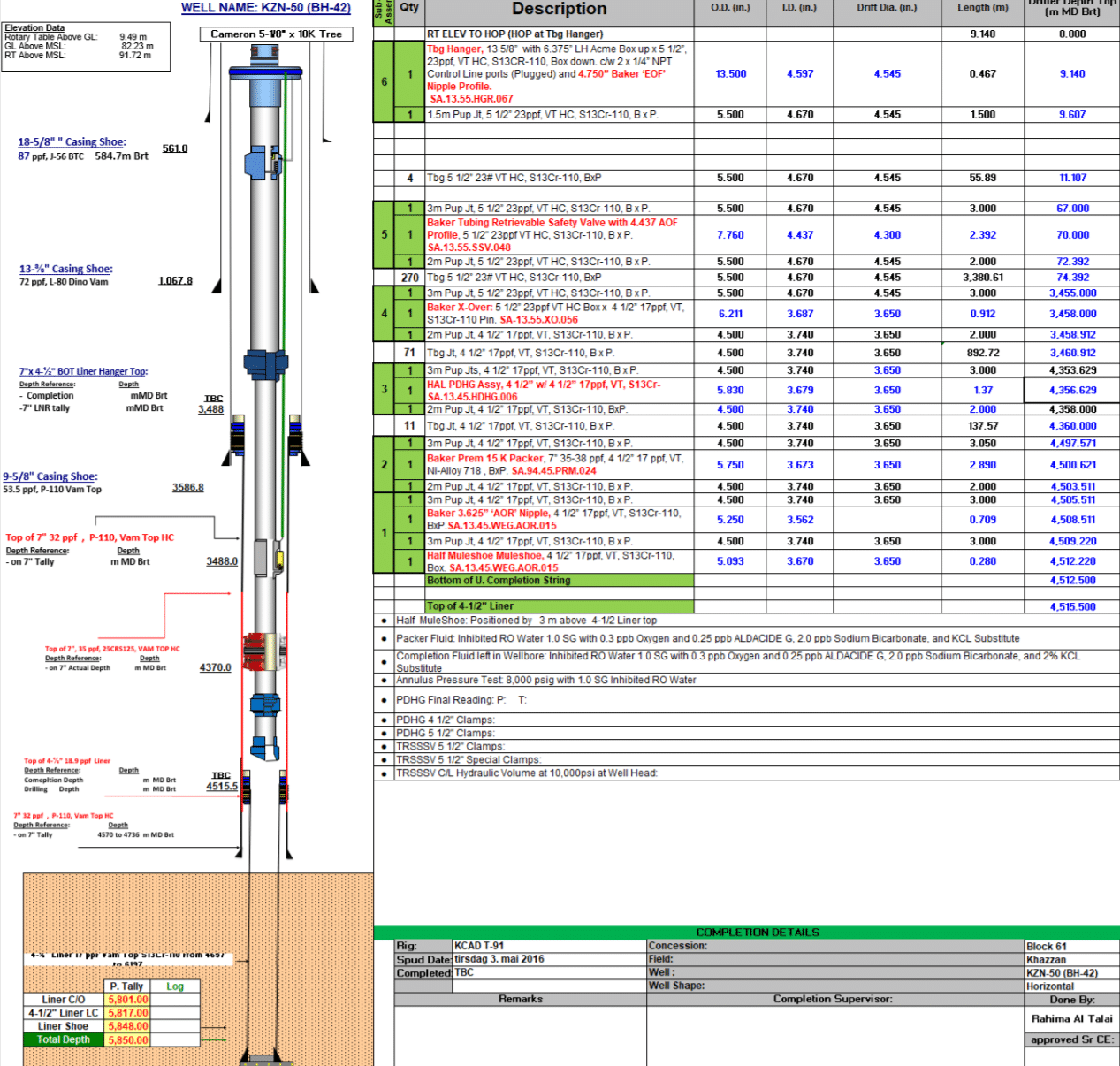

Well Barrier Schematics Verifications

Well barrier schematics verification is crucial for ensuring well safety and compliance. ScanWell offers advanced solutions to help verify well barrier schematics, helping operators confirm barrier integrity and maintain operational safety without intrusive interventions.