Process & Production Optimisation

Services

Process and production optimization in the oil and gas industry focuses on maximizing efficiency, reducing costs, and enhancing recovery from reservoirs while maintaining safety and sustainability. At ScanWell, we support operators in achieving these goals through advanced monitoring technologies and innovative solutions.

Our interventionless surveillance methods provide real-time data on parameters such as flow rates, pressures, and fluid compositions, offering a clear understanding of well and reservoir behavior.

Emulsion & Turbidity Troubleshooting

Emulsion and turbidity issues can significantly impact oil and gas production by reducing efficiency, increasing operational costs, and complicating downstream processing. At ScanWell, we provide advanced monitoring solutions to help operators diagnose and resolve these challenges effectively.

Read more

Full Field Nodal Analysis & Gas network optimisation

Full Field Nodal Analysis and Gas Network Optimization are critical for maximizing production efficiency and ensuring sustainable field operations. At ScanWell, we offer advanced diagnostic and monitoring solutions to support these efforts, enabling operators to optimize flow performance across the entire production system.

Read more

Gas Lift Design verification and Optimisation

Gas Lift Design Verification and Optimization are vital for enhancing production efficiency in oil and gas operations. At ScanWell, we offer proprietary solutions that deliver accurate data and actionable insights to ensure gas lift systems operate effectively.

Read more

Gas Lift Injection Rate Verification

Gas Lift Injection Rate Verification is crucial for maintaining optimal well performance and maximizing production efficiency. ScanWell provides proprietary solutions to accurately monitor and verify injection rates in real-time, ensuring the gas lift system operates at peak efficiency.

Read more

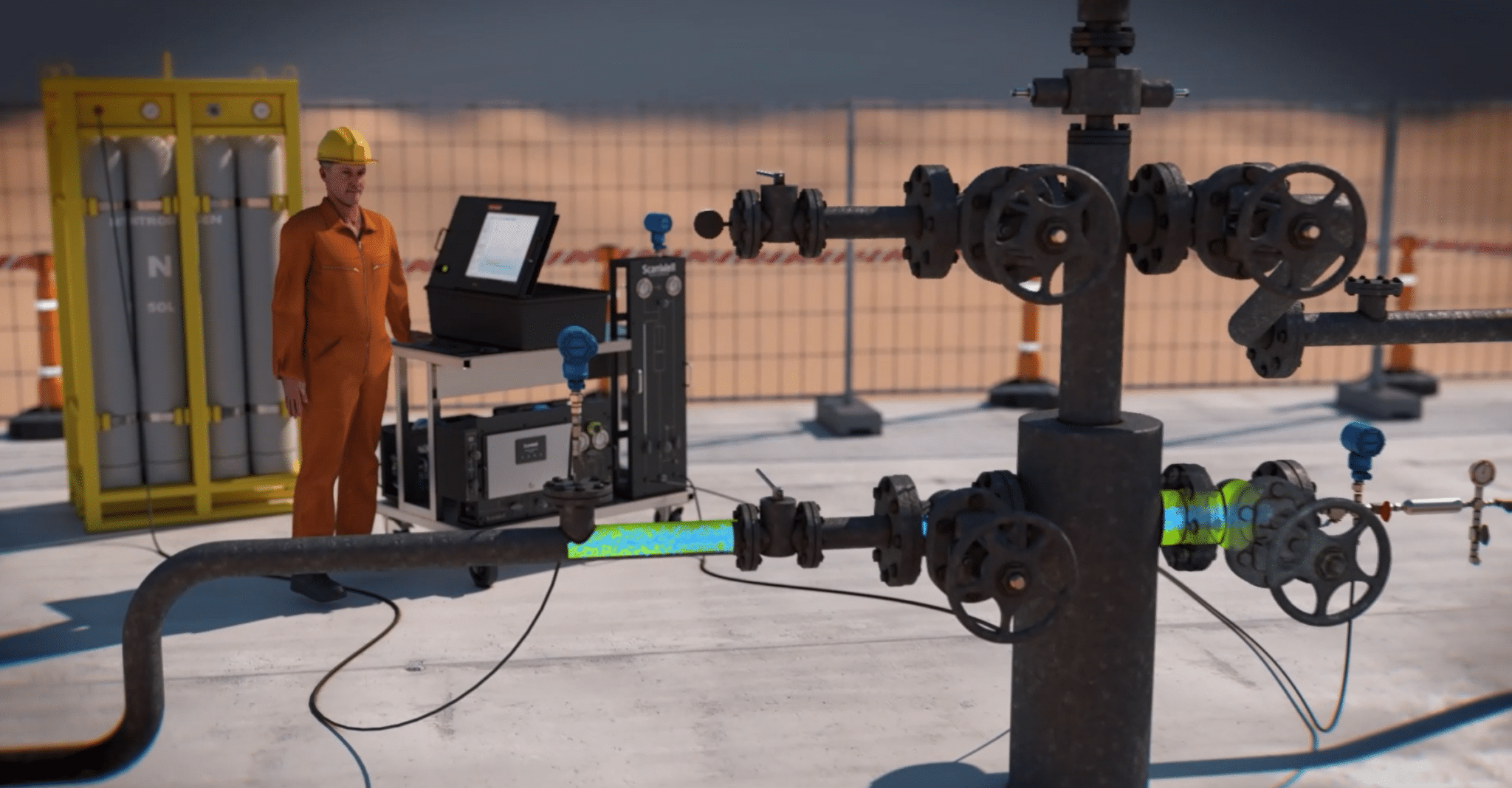

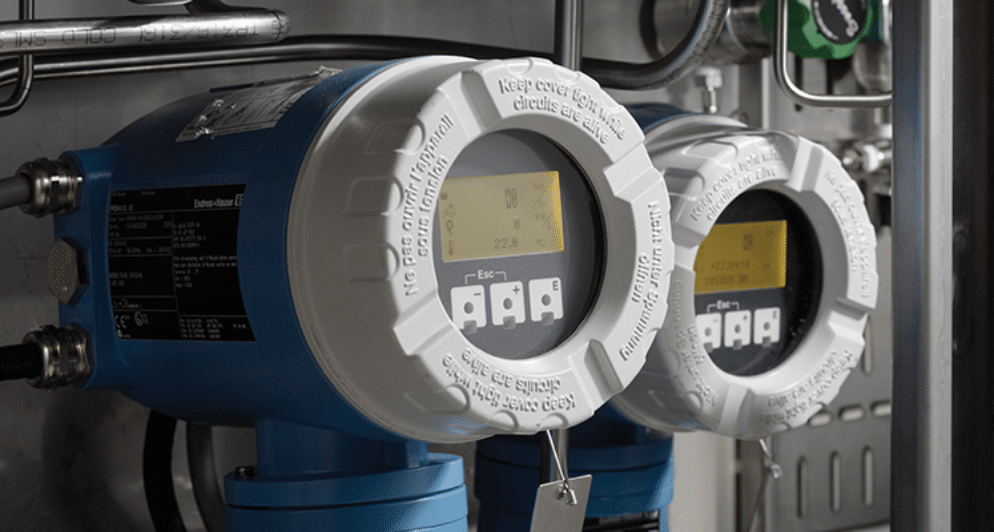

Gas Meter Verification Services

ScanWell N2 dilution method allow operators to validate meter performance in real-time, identify calibration needs, and correct discrepancies. This reduces the risk of errors in flow measurements, improves data quality, and minimizes downtime associated with traditional verification methods.

Read more

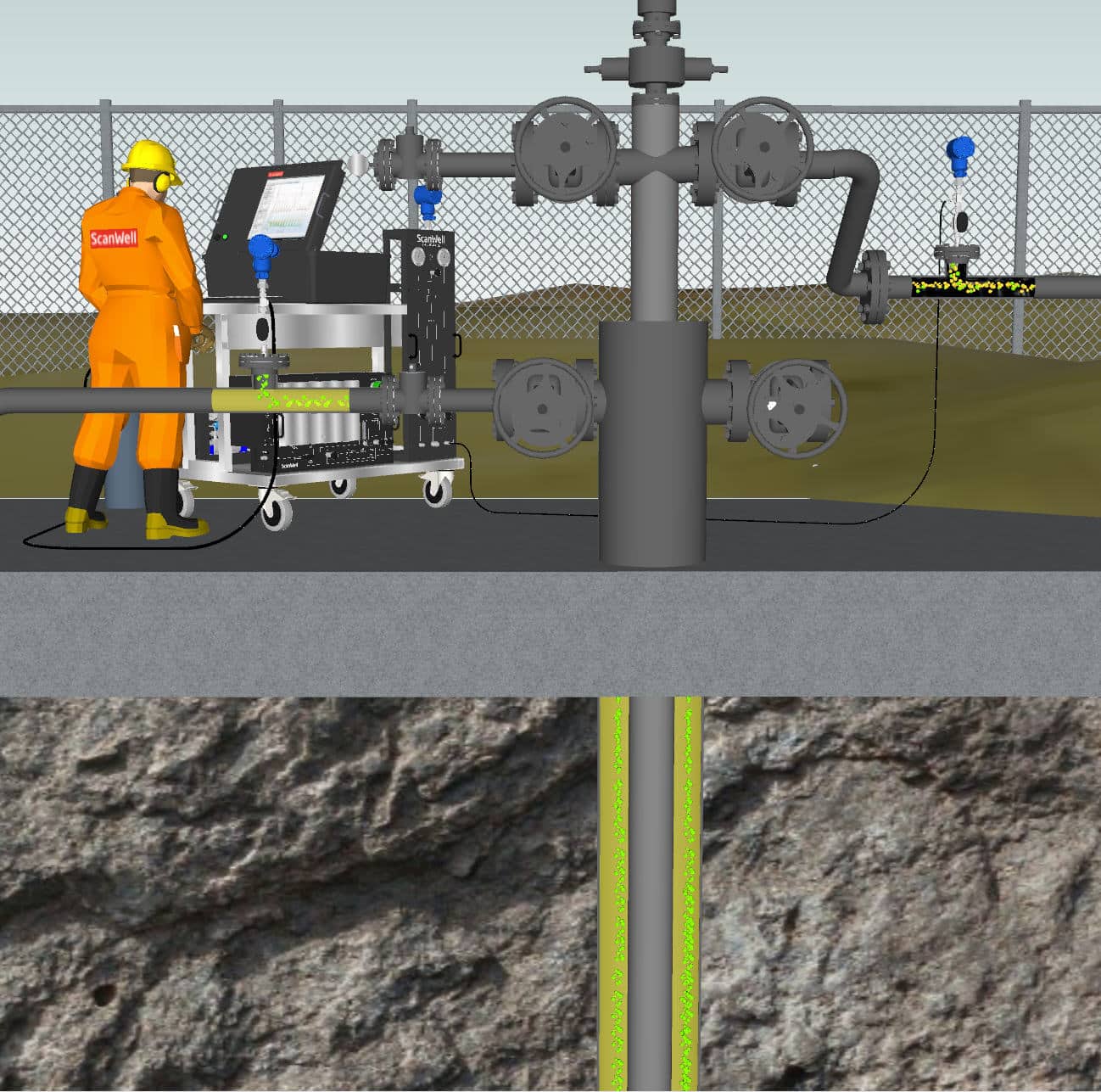

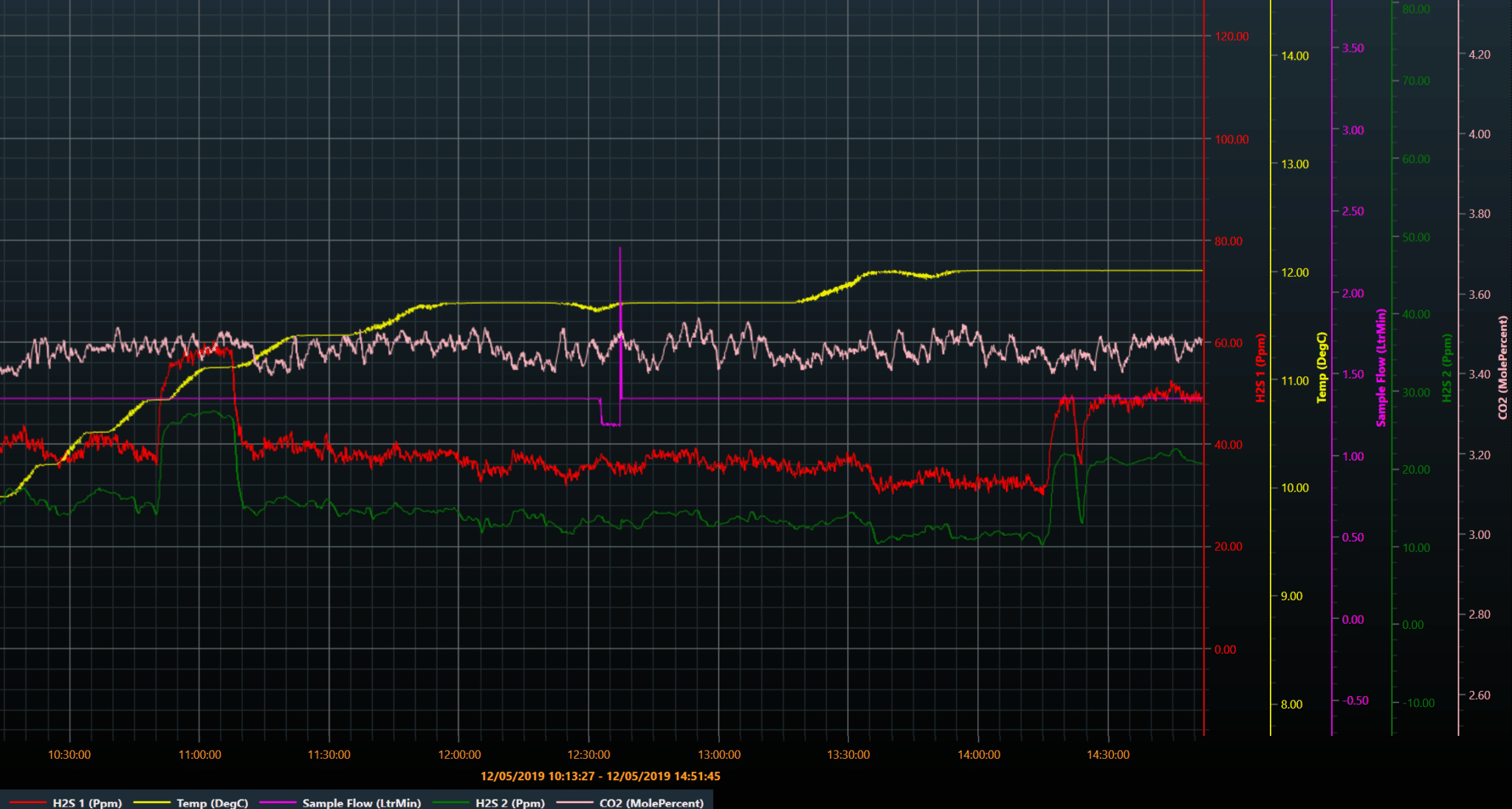

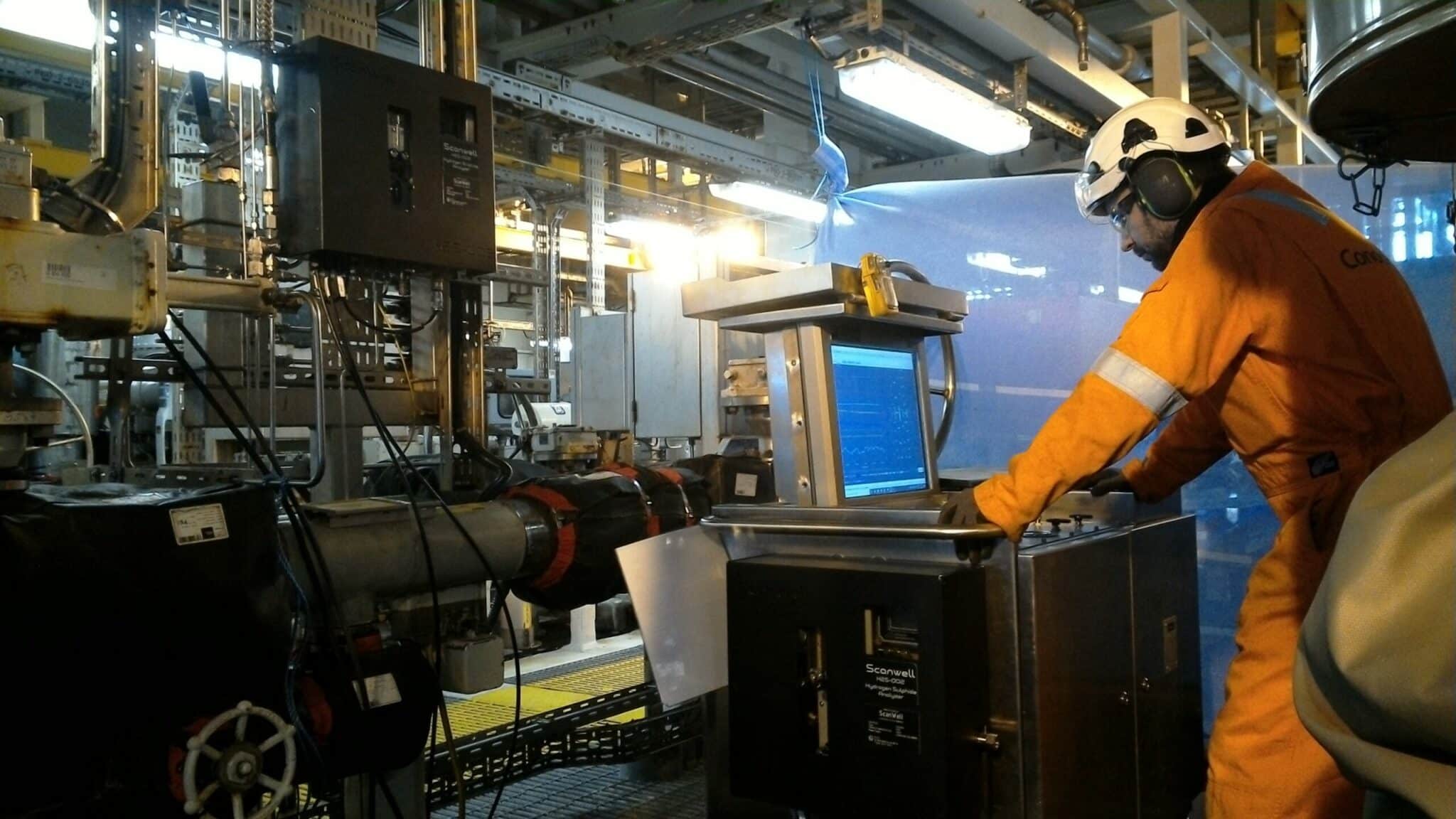

H2S Monitoring of Assets during Flushing

H₂S Monitoring of Assets during Flushing is critical for ensuring safety and operational efficiency in oil and gas operations. ScanWell provides advanced, real-time monitoring solutions to detect and measure hydrogen sulfide levels during flushing processes, ensuring the integrity of equipment and the safety of personnel.

Read more

H2S Process Mapping

H₂S Process Mapping is essential for understanding and managing hydrogen sulfide distribution within production and processing systems. ScanWell provides advanced solutions for real-time H₂S measurement and visualization, allowing operators to identify high-risk areas, optimize process flows, and mitigate corrosion and safety hazards.

Read more

H2S Scavenger Trials & Optimisations

H₂S Scavenger Trials & Optimizations are crucial for efficiently managing hydrogen sulfide levels in production systems. ScanWell offers specialized services to evaluate and enhance H₂S scavenger performance, ensuring optimal chemical dosing and cost-efficiency.

Read more

Monitoring during Well Stimulation Activities

Our services help operators track fluid movements, pressure changes, and flow rates during stimulation, ensuring efficient operations and optimal resource utilization. With ScanWell’s monitoring capabilities, operators can enhance the effectiveness of stimulation treatments, minimize risks, and achieve improved well performance.

Read more

Online CGR/GOR measurements

This cost-effective, accurate solution eliminates the need for traditional separators or inline meters, reduces operational costs, and minimizes environmental impact by avoiding methane emissions and flaring.

Read more

Online Water Cut Measurements

ScanWell is advancing proprietary methods to accurately quantify and monitor water cut in real-time using innovative side-stream equipment, providing continuous and reliable data for enhanced production management.

Read more

PCP Optimisation

By providing real-time data on flow rates, pressure, and pump performance, our solutions enable operators to identify inefficiencies, mitigate risks such as sanding or fluid slugging, and fine-tune operations for maximum output.

Read more

Routine Production Testing

ScanWell’s real-time tracer dilution system offers a precise, efficient alternative to traditional production testing, reducing costs, operational footprint, and crew needs while delivering accurate flow rates and gas compositional analysis.

Read more

Production Chemical performance verifications

ScanWell’ diagnostic techniques help operators evaluate chemical effectiveness and fine-tune dosages. By leveraging ScanWell’s services, operators can reduce chemical costs, enhance production efficiency, and maintain asset integrity.

Read more

Process module performance monitoring

Monitoring the performance of process modules is critical for ensuring operational efficiency and reliability in oil and gas facilities. ScanWell offers surveillance solutions to track key parameters such as flow rates, pressures, temperatures, and separation efficiencies across process modules.

Read more

Separator Optimisation

Our real-time diagnostics help identify inefficiencies like emulsions, carryovers, or excessive retention times, allowing operators to fine-tune processes for maximum efficiency. With ScanWell’s services, operators can improve production output, reduce chemical usage, and enhance the overall performance of their separation systems.

Read more

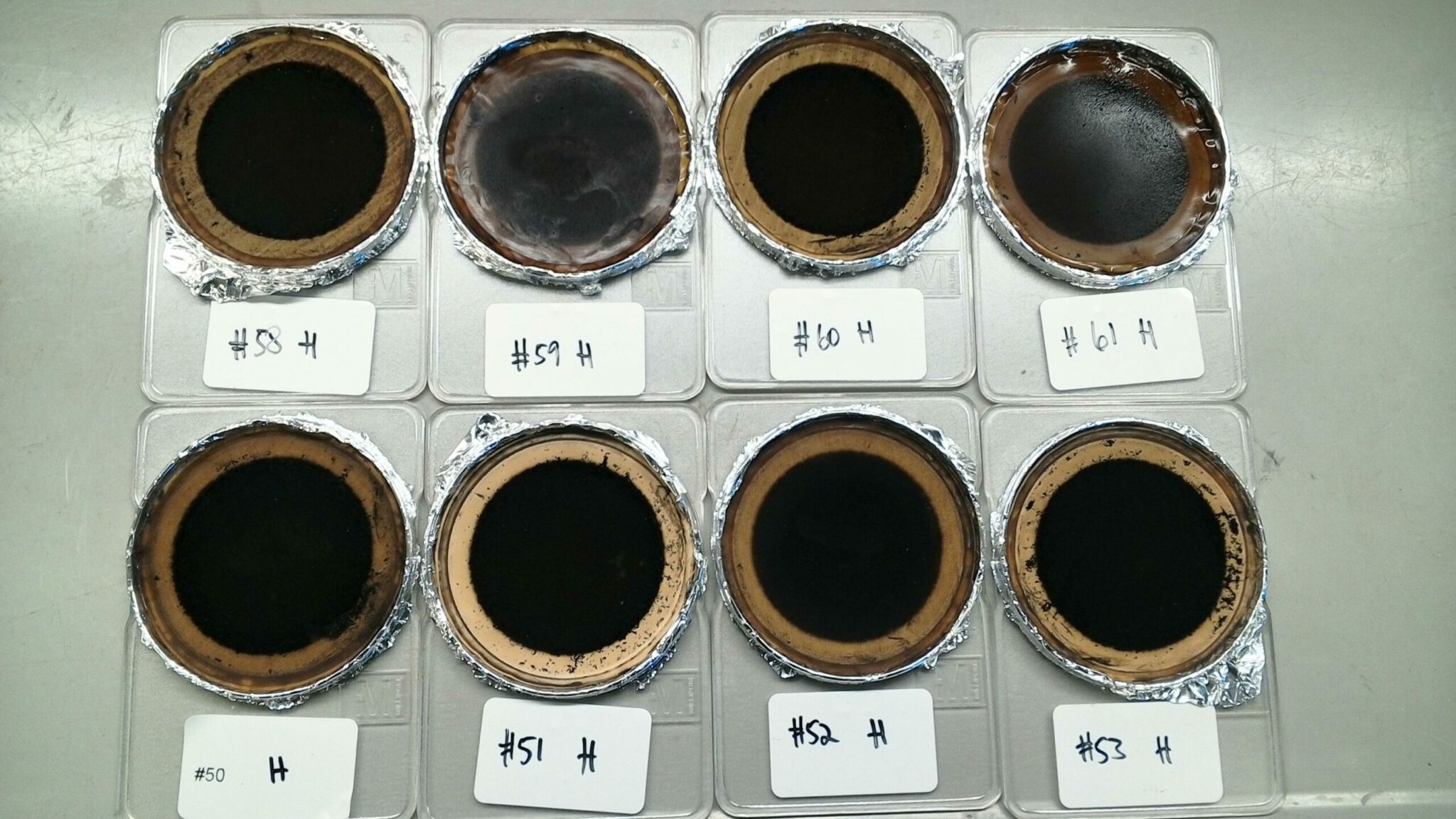

Solids / Asphaltene Sampling, Characterisation and Optimisation

Effective solids and asphaltene management is critical for maintaining production efficiency and equipment integrity. ScanWell offers sampling and characterization services to identify the composition and behavior of solids and asphaltenes in production streams.

Read more

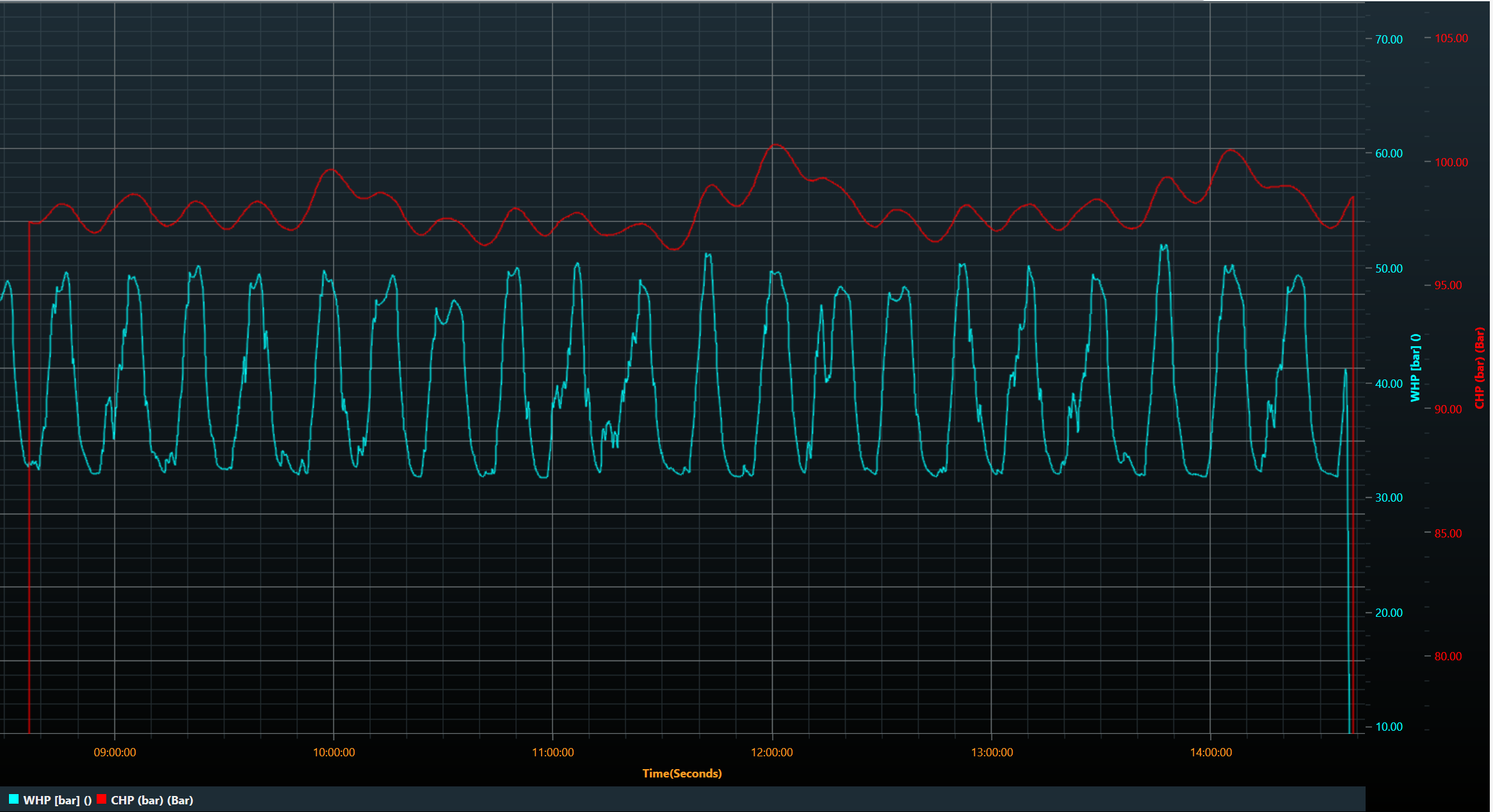

Well Slugging Issues

Well slugging can significantly impact production efficiency and system stability. ScanWell provides advanced monitoring and diagnostic services to identify the causes and reduce the behavior of slugging in wells.

Read more